Funnels

The part of the funnel where the catalyst is made with an angel so that catalyst is flowing into the tube. In the neck of the funnel where the catalyst enters the tube slits are made in order to remove some of the catalyst dust during the loading. A rubber sheet where catalyst is charged will reduce catalyst dust formation and reduce the noise level during the loading.

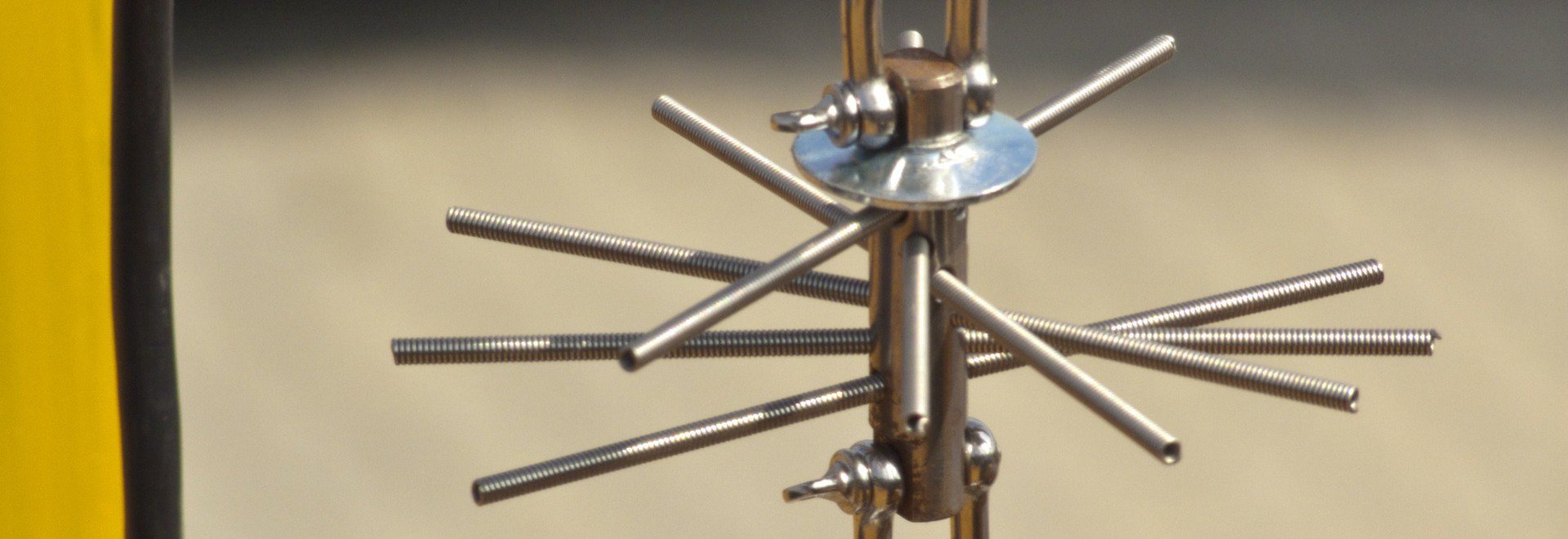

Brushes

The brushes consist of a body with springs through the centre. The springs are equally distributed to cover the cross-section of the tube and are fixed in the body. The number of springs is selected according to the diameter of the tube and the size of the catalyst particles to be loaded. Thickness of the steel springs varies with length and stiffness. The springs shall reduce the speed of the falling catalyst particles, but not stop them, so that the catalyst is loaded without the particles being crushed.

Loading rope

The loading rope is made up with a weight in the bottom connected directly to the first brush. The 3 brushes at the end make up the first part of the rope, an the distance between remaining brushes are approx. 1m. When 2 or more layers of catalyst are to be loaded, the outage from the top of the funnel to each layer is calculated and "flags" of thin steel plate are fixed to the rope in order to let the rope act as a measuring tape.